Automotive EMS

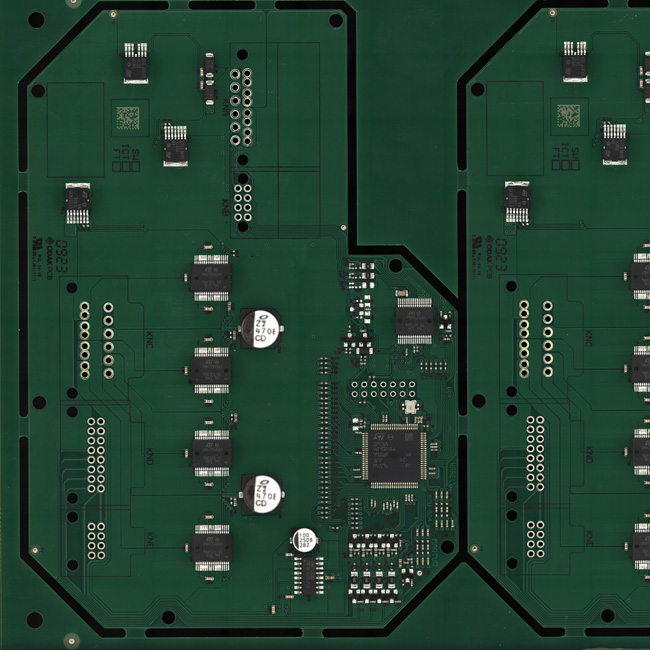

The production of electronic boards takes place in two stages, SMT (Surface Mount Technology) and THT (Through Hole Technology).

New generation machines are utilized for speed, assembly precision, repeatability and traceability.

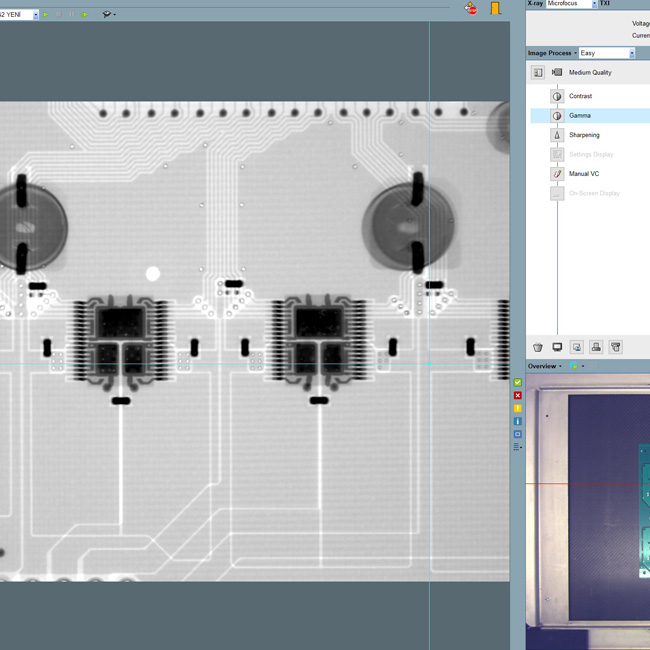

Karel production lines are installed with fully automated SPI (solder paste inspection), 3D AOI automated optical inspection systems, 3D AXI automated X-Ray inspection systems and In-Circuit Test (ICT) systems, which are the requirements of automotive electronics production. In the field of THT (Through Hole Technology) components use selective soldering or wave soldering processes.

For many years, Karel has also been successfully implementing solderless connection technology, which is based on press-fitting suitable components onto PCBs. This technology is characterized by good conductivity and superior mechanical strength, making it possible in the future to equip the appropriate components on many electronic boards with clean connections without soldering.

The entire Karel electronics production area is an Electrostatic Protected Area (EPA) to prevent the presence of electrostatic charges that can damage electronic components, and the production area has a higher atmospheric pressure than the external environment. SMT and THT production areas are in Class-8 standards. Camera productions are also made in Class-6 clean room standards.

All lines are equipped with advanced traceability systems for each individual product, from single component to final product, and the operational structure allows to meet the demands of both large-scale and small series and prototypes.

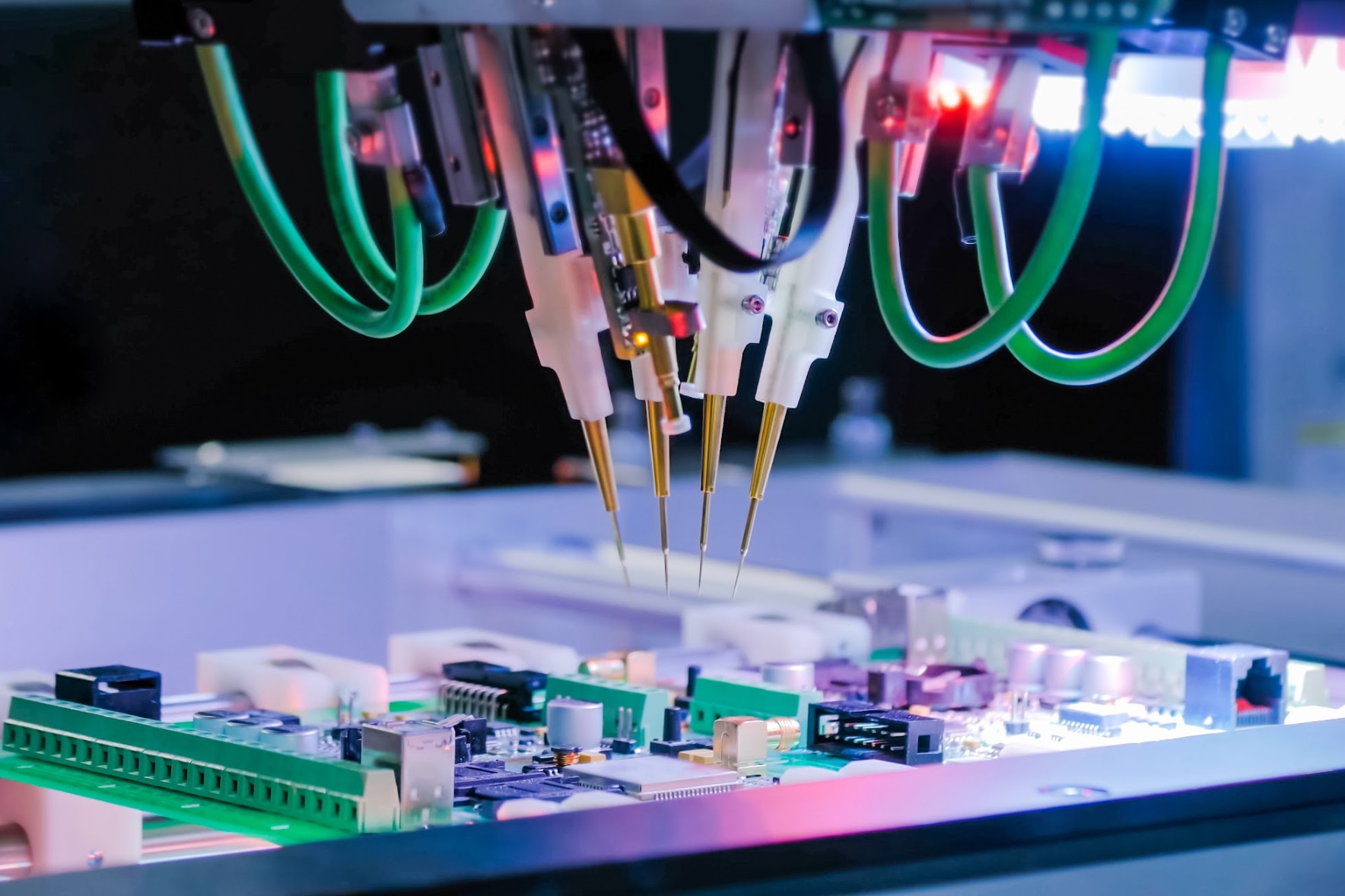

Electronic units are assembled on assembly lines designed by Karel in line with customer requirements, with the help and control of mechanical and optical systems according to the principles of maximum efficiency and ergonomics, and are monitored by monitoring and error prevention systems that do not allow the realization of subsequent stages in case of any error that may occur in any operation. Advanced functional test systems are designed by Karel to match the highly advanced functions and high performance that distinguish its products.

In all cases, for the most complex products, the final test is carried out visually by an operator to detect the smallest defects.

Special processes are available for specific needs: in line with automotive requirements, the camera production lines use the most advanced lens automatic alignment systems. The clearest image is guaranteed.

Very special assembly and test lines were commissioned in Turkey, where production, assembly and testing operations of in-car audio and entertainment systems in line with international automotive standards are carried out.

Strong R&D and Production at Automotive Electronics Standards

With the professional Karel R&D team specialized in their field and high-tech, scalable production processes, we are always with you in all the projects you want to realize.

Contact